|

In the 1960s, the declining U.S. cotton industry

grappled with stiff competition from synthetic fabrics, competitive

international markets, and an outdated image. An unlikely alliance

between rural growers and urban admen helped restore American

cotton to its historic prominence. The co-authors of a new book

about cotton’s comeback spin a compelling yarn.

|

otton

was the miracle fiber of the nineteenth century, when textile manufacturing

was the high-tech, high-growth business of the day. Like all farm

products, cotton was subject to the vagaries of the weather, pests,

and political risks, but for decades it sold into fast growing and

weakly contested world markets. On the eve of the Civil War, cotton

was “King”. Compressed in dirty white bales, upland cotton

from the American South was the developing nation’s largest export,

earning the lion’s share of its foreign exchange. It provided

the “satanic mills” of England with 92 percent of their

supply, and fueled the heart of industrial enterprise in the American

Northeast.

otton

was the miracle fiber of the nineteenth century, when textile manufacturing

was the high-tech, high-growth business of the day. Like all farm

products, cotton was subject to the vagaries of the weather, pests,

and political risks, but for decades it sold into fast growing and

weakly contested world markets. On the eve of the Civil War, cotton

was “King”. Compressed in dirty white bales, upland cotton

from the American South was the developing nation’s largest export,

earning the lion’s share of its foreign exchange. It provided

the “satanic mills” of England with 92 percent of their

supply, and fueled the heart of industrial enterprise in the American

Northeast.

One hundred years later, 300,000 American

cotton growers (cotton farmers are “growers”) were beset

with severe threats to their livelihoods. As the crop’s cultivation

had gradually expanded throughout the world, U.S. cotton had lost

ground in the global market. At home, in their biggest market, man-made

textile fibers – rayon, nylon, and polyester – had launched

a fearsome assault on cotton’s fabric and apparel business. Synthetics

producers were giant corporations, and had the financial muscle to

support research and promotion.

Independent and small-scale as businesses

go, cotton growers were well organized for political purposes. Their

main concerns were to keep themselves from growing too much cotton

and to seek government support for research and relief from hard times

and market fluctuations. The National Cotton Council, created in 1939,

and its offspring, the Memphis, Tenn.-based Cotton Producers Institute

(CPI), had proven adept at influencing national farm policy. But as

the 1960s wore on, these organizations were not able to help growers

compete. Cotton’s share of the market for retail apparel and

home fabrics plummeted from 63% in 1960 to about 45% in 1970, on the

way to its historical low of 33% in 1975.

Farmers supply, but their fate is much

more the story of demand. It was clear that this most traditional

of American industries would need to embrace a fresh approach. Cotton

growers, always attentive to the problems of supply, would have to

learn how to market their crop. The industry was entrenched in 18

states spanning the Old South and new rural Sunbelt, but its new champions

would emerge from the urban corporate world: an advertising executive

from Connecticut, a graphic designer in San Francisco, and marketing

gurus of Madison Avenue.

In April 1970, half a dozen entrepreneurial

growers moved to save their industry. Through the agency of the CPI,

they sought professional help, and found it in the unlikely persona

of Dukes Wooters, an advertising executive at Readers Digest. Wooters

had a classic New England pedigree: the Taft School, Lehigh University,

military service in World War II, and Harvard Business School. He

knew next to nothing about cotton.

Blessed with an unforgettable name and

a deep arresting voice, Wooters was a hard-driving salesman, a marketing

man with great instincts for what would move off the shelves. At 53,

he had just turned-around the Digest’s sagging operation in Brazil

and was looking for one last great career challenge. “Dukes had

style,” one grower said. He shopped at Brooks Brothers, but to

prepare for his interview with the CPI leadership, he cruised through

Macy’s. “I looked around,” he said, recalling his surprise,

“and there was hardly any cotton.” Brooks Brothers was the

carriage trade; Wooters wanted to move cotton back into the mass market

by the trainload.

Clearing the Ground

No city was more closely identified

with a commodity than Memphis was with cotton. CPI’s research

staff was based there, and a small marketing organization, comprising

mainly Memphians, was lodged in tatter-down offices in the Empire

State Building. Wooters let them go, all but one. As Wooters tried

to explain to one nonplussed cotton grower, “you’re not

just raising a crop, you’re selling fashion on Seventh Avenue.”

To compete, growers would have to embrace

the big-city, consumer-driven culture of marketing. CPI’s headquarters

were moved to New York. Its research operations were transferred to

Raleigh, near North Carolina State University’s textile school

and near many of the country’s major cotton textile manufacturers.

Wooters determined that CPI would have to change its name, too. It

was a publicly funded body, but Wooters chose “Cotton Incorporated.”

He intended to run Cotton Incorporated as if it were “a real

company,” like Readers Digest or, for that matter, cotton’s

nemesis, that great innovator in synthetic fibers, DuPont.

Cotton Incorporated had a total annual

operating budget of just $20 million to pay for marketing, research

and administration. Its funds came from a voluntary contribution of

cotton growers channeled to it by the Department of Agriculture’s

Cotton Board (Today the assessments are mandated by law.) Yet the

company’s mission was ambitious, embracing almost every aspect

of production and distribution. Wooters saw the cotton market as a

continuous loop that bound thousands of growers to millions of consumers

through the good offices of textile mills, clothing manufacturers,

and retailers. The relationships all along the loop were dynamic and

interdependent. A “total marketing” approach was necessary.

Total marketing meant developing plans

to link the mills, clothing manufacturers, retailers and consumers

together into a mutually reinforcing chain of profit maximization.

The mills were the first customers, and they would be offered technical

assistance free of charge. Caring for them was crucial because they

preferred synthetics. Cotton, like wine, was highly variable in quality;

synthetics were uniform, easier and cheaper to process in volume.

Total marketing meant conveying back

to those engaged in research and technical services ideas from the

marketplace for new and improved fabrics and finishes. It meant arming

manufacturers and retailers with new fashion ideas that could be interpreted

in cotton and cotton-synthetic blends.

All that would be possible if, and only

if, mills, manufacturers and retailers were confident that the demand

for cotton was there. Most dramatically and publicly, Cotton Incorporated

would stimulate consumer demand with advertising and promotions, not

of cotton as an agricultural commodity – “that funny looking

white stuff,” as Wooters called it – but of cotton as a

brand.

Cotton’s Seal

The first step in converting cotton

from an agricultural commodity into a consumer brand was the creation

of a new image. Cotton, Wooters felt, had an image problem going back

a lot farther than the stodgy dungarees-and faded-cotton-frock-memories

of rural America. Ironically, the image of rural work clothes would

prove to be a key to cotton’s salvation.

While visiting Levi Strauss in 1971,

Wooters called on the noted designer Walter Landor in San Francisco,

who presented 12 versions to Cotton Incorporated. The chosen design

for the “Seal of Cotton” – one that Lander’s daughter,

Susan, had conceived, would become one of the most successful trademarks

in the annals of marketing. It was simple and engaging – a white

cotton boll, rising up from the two T’s of the word “cotton,”

laid against a background of earth-tone brown.

The seal appeared in 1973, and almost

instantly gave cotton a new identity, making a deep impact on public

awareness, a rare masterpiece of graphic design-as-communication.

The design conveyed several positive messages. If nature was good,

then cotton was good. Cotton had roots, but it also had bloom. Cotton

was pure, soft, comforting and natural. Cotton was something familiar

that you wanted to have and to keep around.

Creating Consumption

From its inception, the seal would stand

at the center of an intensive and innovative advertising campaign

designed to “pull” cotton back into consumer consciousness.

The broad middle class of consumers of Wooters’s generation –

those who came of age in the 1930s and 1940s – had largely forsaken

cotton for the wash-and-wear convenience and economy of synthetics.

But it happened that their children, however, the baby boomers born

between 1946 and 1964, were clad in cotton, or, to be more exact,

in denim.

Denim’s history reached back into

the nineteenth century. Though not indigenous in origin, denim –

used in dungarees or overalls – had become the quintessential

American fabric. In the 1960s, denim took on a new appeal for the

young. Blue jeans looked unkempt, required little care, were comfortable

and, most important, projected an image that rebuked the buttoned-down

fashion statements of the boomers’ parents’ generation.

An emblem of protest, jeans were bound up with rebellious acts ranging

from recreational drug use to civil rights and antiwar demonstrations.

The worry for cotton growers was that

boomers might abandon denim as they aged. The problem, then, was not

just to sell jeans to contemporary customers, but to do what synthetic

manufacturers had done so well: sell “fiber consciousness.”

In order to craft its own approach to advertising, Cotton Incorporated’s

marketing staff spent months studying the master, DuPont, the leading

synthetic-fiber manufacturer. What they learned was that they must

focus the market’s attention on the performance characteristics

of cotton garments.

Television Guides

Cotton’s consumer advertising began

in 1971. The medium was almost exclusively network television. This

tactic set cotton apart from other agricultural marketing programs.

The first ads in 1971, created by the Jack Byrne Agency, honed in

on a budding cultural notion that had its origins in the boomers’

counterculture of the 1960s: if something was “natural,”

then it must, somehow, be better. These ads carried the tag line “Cotton:

It’s a Natural Wonder” (with “Brought to You by Cotton

Incorporated and America’s Cotton Growers” tucked in at

the bottom of the screen). Viewers learned that they liked those scruffy

old blue jeans because “Levi’s‚ still makes them –

all 100 percent cotton.”

The effectiveness of Cotton Incorporated’s

advertising can be ascribed to the company’s long running relationship

with the advertising agency, Ogilvy & Mather (O&M), whose

co-founder David Ogilvy was an evangelist for branding. Cotton Incorporated

had little to spend by large corporate standards, and the dispersion

of its funds was politically sensitive. Hence, O&M faced a dilemma.

How could it create ads for cotton that were high impact yet cost

effective, carefully targeted and yet universally appealing? The seal

was key. Animated for television, it grew in a few seconds before

the viewer’s eyes, up from the good brown earth into a full-blown

soft, white cotton boll.

O&M found selective, high-impact

venues for cotton without breaking the bank. For example, Cotton Incorporated

focused most of its 1976 advertising dollars on the Olympic Winter

Games at Innsbruck in Austria. A fruitful media tie-in was cotton’s

regular appearance, starting in 1977, on NBC’s TODAY Show, an

association that vaulted Cotton Incorporated into the front ranks

of consumer advertising. As more cotton products were selected for

promotion, familiar television personalities delivered live commercials

on the set. Viewers saw Barbara Walters in a bright Hawaiian shirt

posed beside the Seal in a tropical setting, exuding confidence that

cotton was “doing a lot to make your life more comfortable. I

know it’s making my life comfortable right now.”

It all worked like a charm, producing

brand awareness and stimulating consumption. After one year, 18% of

consumers could identify the seal. By the end of 1976, when awareness

of the seal jumped to 46%, cotton’s market share edged upward

to 36%. (Today more than 70% of American consumers recognize the symbol,

even without the word “cotton.”)

The seal was used, for a transitional

period, to mark cotton-dominant “blends,” one way to help

re-capture market share. The 60/40% cotton/synthetic shirt became

commonplace on men’s store shelves. Then in 1977 and 1978, Levi

Strauss attempted a denim blend. The mix was modest (never more than

15% polyester), but the strategy was a marketing disaster for the

jeans maker. An aroused Cotton Incorporated pounded away at the heresy,

reminding consumers that the denim they had known and loved since

childhood was “100% cotton.”

A revised denim campaign featured pretty

young women viewed from the rear, in tight denim jeans, available

– along with lawnmowers, washing machines and power tools –

at your friendly hometown Sears. The implication was clear: in a world

filled with fakery, cotton was real. It performed the way you wanted.

Wearing it made you look and feel good, not just physically, but emotionally

too. The long-term message was: “Come home to cotton!”

Touting Performance

Cotton’s market share took off

in the 1980s, from 36 to 50%. The nation was emerging from a decade

that had included defeat in Vietnam, two oil shocks, rampant inflation,

and deteriorating competitiveness. The economy and corporate America

were now in the process of repair, and the nation’s mood edged

toward a new confidence. Cotton’s advertising voice grew more

confident, too.

O&M co-opted an idea from the synthetics

manufacturers, of identifying cotton as a “performance”

fiber. (This was a claim made possible by technical improvements in

cotton fabrics, driven partially by better breeding programs.) Television

viewers were wowed as ballerina Heather Watts pirouetted in front

of New York’s Lincoln Center and proclaimed the wonders of her

100% cotton Ship’n Shore™ shirts: “All cotton plus

permanent press: now that’s high performance.”

The “True Performance” campaign,

originated at Cotton Incorporated and developed and executed by O&M

evoked probably the most compelling image of cotton since coining

of the phrase “King Cotton” in the 1850s. Cyclists, sailors

and pole-vaulters strenuously “performed” in their cotton

duds, as “True Performance” dominated Cotton Incorporated

advertising through the eighties. The campaign included an elaborate

labeling effort at the retail level. Attractive “True Performance”

hang-tags, depicting the slogan and the Seal, appeared on millions

of garments in the biggest retailers and smallest specialty shops,

alike.

“True Performance” was

a watershed campaign. But demand for particular types of cotton apparel

and home furnishings, like demand for many other consumer products,

inevitably varied with fashion and the whim of consumer tastes. The

challenge therefore was to even-out these peaks and valleys by cultivating

loyalty to cotton as an essential component of the good life.

“The Fabric of Our Lives”

Dukes Wooters left Cotton Incorporated

in 1982, and in 1987, its president Nicholas Hahn took a new approach

to advertising. In focus groups and one-on-one interviews, people

were invited to talk about fiber, fabrics, garments, cotton, wool,

polyester, and anything to do with clothing. Something surprising

was discovered. Interviewees said that wool was warm and scratchy,

and that polyester was sticky, hot and did not breathe. But they also

professed “something” (they did not know what exactly) “about

the feel of cotton.” While talking about cotton, they tended

to touch themselves, whether or not they were wearing it. Some prompting

got subjects to talk about how they liked having cotton close to their

skin, and how little babies get wrapped in cotton, and other emotion-laden

images connecting cotton with life’s various stages.

Based on this news, O&M concocted

the deceptively simple phrase, “The Fabric of Our Lives‚”

for a campaign that would become one of the most memorable in advertising

history. The documentary filmmaker Leslie Dektor’s avant-guard

realism, aimed at showing people as they were, did not talk about

performance features at all. The target audience had changed, so now

the message was intergenerational. Cotton was authentic, from “cradle

to grave,” not just for the baby boomers, but their parents and,

before long, their children, too.

For the launch of the Fabric of Our

Lives campaign, Hahn authorized an expenditure of $2 million of the

company’s $7 million advertising budget in one day – Thanksgiving

1989, the day before the single largest shopping spree of the year.

It was the day when families watched television dawn to dusk, from

the Macy’s Parade through professional football games to the

“Sound of Music.” Cotton commercials blanketed the screen,

as one hundred fourteen million viewers saw and heard them, over and

over again.

The size of Cotton Incorporated’s

expenditure enabled O&M to negotiate for reinforcing billboard

space. “Macy’s Thanksgiving Day Parade, Brought to you [in

part] by Cotton Incorporated. Cotton: The Fabric of Our Lives.”

Subsequently, O&M sought to sustain Cotton Incorporated’s

media “presence” with key franchise positions – twice

a week with Willard Scott on TODAY; beside Peter Jennings on ABC News;

on Late Night with Jay Leno; and on other highly rated shows.

Getting Emotional

Cotton and the good life went together,

like parents and children in happy homes. Cotton’s unvarnished

advertising “reality” confounded some critics, but it was,

in O&M’s word, “emotionally relevant.” In the late

1980s and 1990s, the linkage between liking a product and perceiving

it as authentic accounted for some of the great brand successes of

the era, like Starbucks™, The Body Shop™ and Virgin Atlantic™.

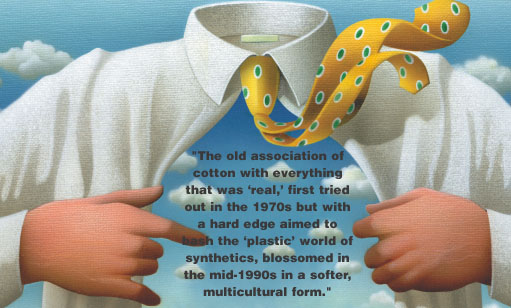

The old association of cotton with everything that was “real,”

first tried out in the 1970s but with a hard edge aimed to bash the

“plastic” world of synthetics, blossomed in the mid-1990s

in a softer, multicultural form.

In the 1990s, the Fabric of Our Lives‚

campaign embraced more modish themes. One ad featured an African-American

family, sitting around the dining room table in a reprise of the Norman

Rockwell image of Thanksgiving dinner. There are multiple generations,

nattily turned-out, nice up-market surroundings, lots of smiles. “How

different can we be,” went the voiceover for a spot featuring

a rainbow coalition of cotton-clad actors, “when we all love

to wear the same thing?” The actors in the ads appeared younger.

Research showed that turn-of-the-millennium teens and young adults

liked cotton well enough but displayed lower “fiber-consciousness”

than their parents. The job of educating the market was never-ending.

On the cusp of the twenty-first century,

an abrupt change occurred in workaday fashion that was tailor-made

for cotton. Corporate America went casual, and cotton supplied the

alternative, as male corporate America doffed its woolen suits and

female corporate America its linens and silks, for open collared shirts

and comfortable-fitting khakis. “What would it be like,”

came the question as the screen filled with diverse hard-working Americans,

“if we all dressed as if work were fun?”

Corporate casual dress, of course, was

a hallmark of the dot-com era. Yet while that particular bubble has

burst, cotton’s staying power has not. Consolidating the gains

it had made in the 1970s and 1980s, cotton closed the millennium with

a more than 60% share of the market for retail apparel and home fabrics.

What other industry (or company, for that matter) has ever lost nearly

half its market share and won it back?

Competition and Survival

The story of cotton’s renaissance

is not solely a story of consumer marketing. Dukes Wooters had envisioned

from the outset that Cotton Incorporated would have to meet rising

consumer expectations with ever-improving fiber quality, or gains

in market share could not be sustained. Competitive threats –

from low-cost synthetics and low-wage foreign producers – would

have to be checked with relentless quality improvements and cost-reductions

on the farm.

The practical result of his vision is

that the American cotton one wears today is far superior to the cotton

of forty years ago. It’s easier to fabricate and to care for.The

industry invests in research and development spanning fundamental

agricultural science to farm-level technological improvements. Today,

cottonseed research traverses the cutting edge of genetic engineering.

Cotton can be grown in colors. Enterprising growers invest in automated

tractors that can till the land to fine precision, locating their

positions with within two centimeters, day or night, in all weather,

increasing yields, lowering labor costs. And hungry textile mills

(though they have mostly moved overseas) get what they want most:

American cotton that is longer, stronger, finer, cleaner, and cheaper.

It’s a good thing, too. Cotton

growing is a ruthlessly competitive global enterprise. Cultivated

in more places around the world, cotton trades more freely than ever.

American growers have learned to manage demand but cannot administer

price. As quality has improved and as costs, and prices, have come

down, it has been a boon to consumers, a challenge to growers. Despite

mounting subsidies from the government, to compensate them for losses

in low-price commodity markets, the pressure on cotton growers to

deliver higher quality for less is unabated. Staying competitive demands

a high level of scientific and business sophistication. It requires

investment in technology, management, and marketing, and a broad-based

knowledge of world affairs, from the weather in Australia to political

conditions in Pakistan, from what’s fashionable in Paris to what’s

happening in the world’s genetic and biochemical laboratories.

In this dynamic environment, only the

strongest survive. Farms have consolidated to increase capital and

scale economies. Marginal land has been abandoned, given over to other

crops, converted into housing developments and shopping malls. That

some 30,000 cotton growers (just a tenth of the number in 1960!) are

still in business in the U.S., producing more and better cotton at

lower cost, is testimony to their collective mastery of the market.

George David Smith is clinical professor

of economics and international business at NYU Stern. He is a member

of the faculty of the Berkley Center for Entrepreneurial Studies.

Timothy Curtis Jacobson is a partner

in The Winthrop Group, Inc. This article is adapted from their new

book, Cotton’s Renaissance: A Study in Market Innovation (Cambridge

University Press).

![]()